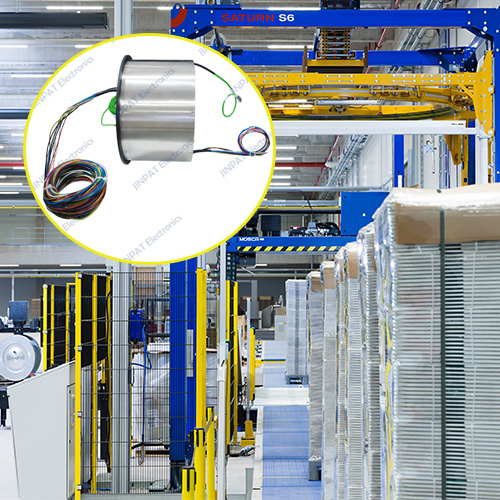

JINPAT High-Capacity Hollow Slip Ring with Massive 250mm Bore And Industrial Ethernet

2025-09-26

What is a Hollow Shaft Slip Ring and Why is it Crucial?

In rotating machinery, providing power and data to a spinning part is a classic challenge. Tangled and worn cables lead to downtime and maintenance nightmares. A hollow shaft slip ring solves this by providing an electrical interface that allows for seamless 360° continuous rotation between a stationary and a rotating structure. The "hollow shaft" design is key—it creates a central passageway (the bore) for integrating other machinery components like pneumatic arms, hydraulic lines, coolant hoses, or sensor cables, keeping them organized and protected while the machine rotates freely. This eliminates cable wrap-up, reduces wear, and enables more compact, efficient, and reliable machine designs.

Product Highlights:

1.Unmatched Design Flexibility with Massive 250mm Bore: The enormous 250mm (≈10 inch) thru-bore is a standout feature. It offers ample space to route a bundle of media supplies—air pipes, water lines, servo motor cables—directly through the center of the slip ring. This simplifies mechanical layout, protects critical components, and allows for cleaner, more innovative packaging machine designs without the clutter of external rotary unions or cable carriers.

2.Powerful & Versatile Signal Transmission: This isn't just a pass-through; it's a high-performance transmission hub. It consolidates multiple energy and data needs into one reliable point:

High-Power Circuits: 6 channels of 35A current to drive powerful motors, heaters, or actuators on the rotary side.

Control Power Circuits: 4 channels of 10A current for sensors, solenoids, valves, and other control elements.

High-Speed Data Link: 1 integrated channel for Ethernet POWERLINK (a real-time Industrial Ethernet protocol), ensuring deterministic, jitter-free communication for synchronized motion control, high-speed I/O, and real-time data acquisition from rotary sensors.

3.Built Rugged for Demanding Environments: Engineered for reliability where it counts:

Vertical Mounting Capability: Designed to perform perfectly in vertical orientations, common in packaging applications like rotary fillers or index tables.

High Ingress Protection: IP54 rating shields the internal components from dust and water splashes from any direction, ensuring stable operation even in wash down environments.

Exceptional Longevity: With an operational life of up to 50 million rotations, it guarantees outstanding durability and significantly reduces maintenance needs, maximizing your production uptime.

Ready to cut the cord and unleash the full potential of your packaging machinery?JINPAT slip rings are reliable.