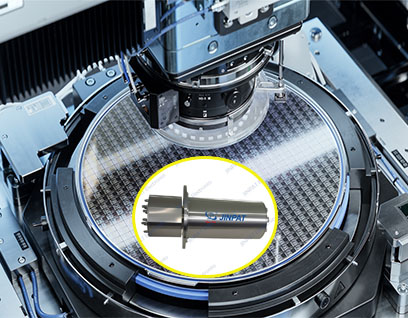

Withstands 200℃ high temperature and is leak-proof: JINPAT slip rings aid in precision semiconductor manufacturing.

With the development of the semiconductor manufacturing industry, the requirements for the reliability and cleanliness of core components in equipment are becoming increasingly stringent. Even minor contamination or performance fluctuations can lead to a decrease in product yield. To better address these issues and keep pace with the development of the semiconductor industry, JINPAT has launched the LPT hollow shaft slip ring, which features high-temperature resistance and vacuum environment adaptability. As a key component for rotary connections in semiconductor equipment, this product is widely used in wafer processing, vacuum deposition, and etching systems. The following highlights its two core features in high-temperature and vacuum environments.

1. High Temperature Resistance: Stable Operation Above 200℃

Many processes in semiconductor manufacturing, such as high-temperature annealing and plasma treatment, involve high-temperature conditions, requiring slip rings to operate continuously above 200℃ without failure. JINPAT LPT hollow shaft slip rings have been specifically optimized for this requirement:

Utilizing high-temperature resistant materials and a special insulation design, they ensure stable electrical performance in high-temperature environments.

The SUS304 stainless steel housing provides excellent heat resistance and structural stability.

2. Vacuum Environment Adaptability: Contamination Prevention and Sealing Guarantee

Semiconductor vacuum chambers have stringent cleanliness requirements; any oil, particles, or metal ion contamination can compromise process performance. JINPAT LPT slip rings offer multiple advantages for vacuum applications:

Oil-free rotor design ensures a clean vacuum environment.

Multi-layer sealing structure effectively prevents leakage and maintains vacuum stability.

Stainless steel terminals eliminate copper ion contamination, meeting semiconductor process requirements.

Hollow shaft design facilitates integration and supports multi-functional equipment needs.

JINPAT LPT hollow shaft slip rings, specially designed for high-temperature and vacuum environments, not only meet the extreme requirements of semiconductor equipment for temperature, cleanliness, and reliability, but also offer flexible customization capabilities to adapt to various application scenarios. Their innovative features, such as high-temperature resistance, anti-contamination materials, and sealing technology, make them an indispensable component in the semiconductor industry, driving precision manufacturing to higher levels. In the future, as semiconductor technology continues to advance, JINPAT will continue to optimize its products, providing the industry with more efficient solutions.