JINPAT News

Professional slip ring solution technology

No matter how difficult your problem may be, we will solve it one by one and provide you with the highest quality solutions!

-

JINPAT Showcases New Medical Slip Rings at the Shenzhen International Medical Equipment Exhibition

JINPAT, an internationally renowned slip ring manufacturer, participated in an exhibition. It showcased high - end medical slip rings developed to meet various medical needs. Committed to quality, it will reveal new solutions in the future.

-

which material is a slip ring made?

Slip rings are made of different materials based on application needs. Conductive rings use copper etc., brushes use carbon - graphite, and housings use metals. Material selection considers multiple factors.

-

How dose a slip ring work?

A slip ring transfers electrical signals, power or data between stationary and rotating parts. It has conductive rings on the rotor and brushes on the stator. JINPAT slip rings, made with quality materials and innovative design, offer excellent performance for rotating systems.

-

Introduction to Several Key Technical Performance Indicators of Slip Rings (Part 1)

Slip rings are precision, vulnerable electromechanical components. JINPAT's slip rings are globally used. This article introduces key technical performance indicators like static & dynamic contact resistance, friction torque, insulation strength, and service life, and how JINPAT ensures good performance.

-

Introduction to Several Key Technical Performance Indicators of Slip rings (Part 2)

This text continues discussing slip ring performance. It covers friction torque (startup & dynamic, related to brush pressure), insulation strength (affected by sealing gel), and service life (influenced by multiple factors). JINPAT optimizes for better performance.

-

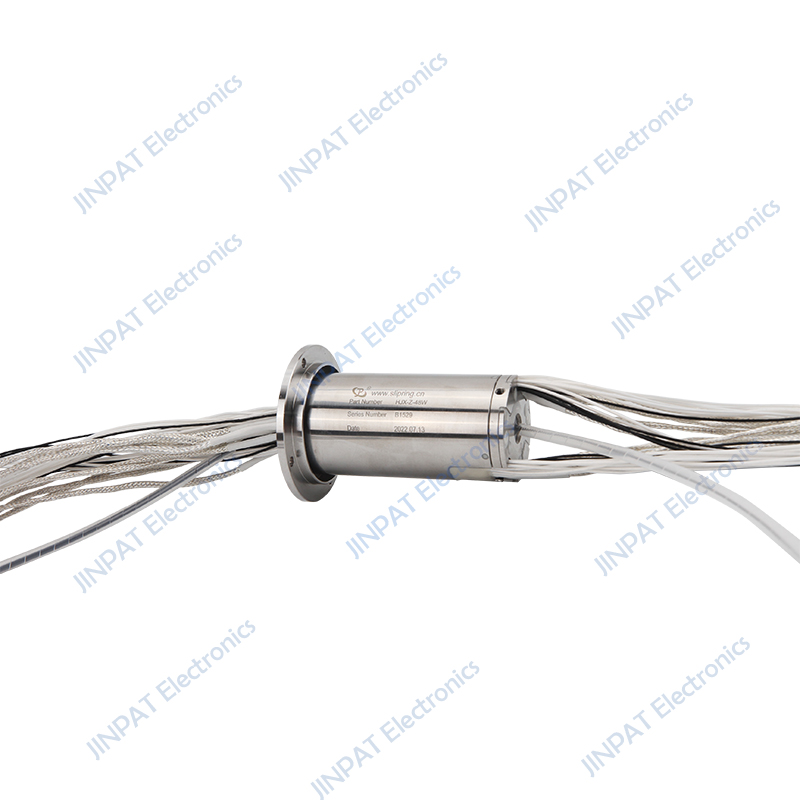

Innovative Multi-Functional Slip Ring Developed by JINPAT

JINPAT, a professional slip ring manufacturer with nearly 30 years of experience, has developed a high-current integrated 32-channel fiber optic slip ring, marking a significant breakthrough. This innovative product combines hollow shaft, high current, multi-channel fiber optic transmission, and high protection levels, making it ideal for demanding environments. It supports 400A current for 12 channels, integrates 32 fiber optic channels, and has an IP66 protection rating. Designed for large cab

-

JINPAT Partners with Clients in 2024, Embarking on the Journey of Slip Ring Innovation Together

JINPAT is a leading high-tech enterprise specializing in slip ring design and manufacturing, serving industries like automation, robotics, aerospace, and defense. With over 80 engineers and global R&D partnerships, JINPAT has secured numerous patents and delivers innovative slip rings, including capsule, through bore, pancake, and hybrid types. Committed to craftsmanship and customer-centric solutions, JINPAT combines advanced R&D and manufacturing to meet market demands. In 2024, JINPAT

-

JINPAT Organizes Birthday Party for Employees

JINPAT recently hosted a warm and festive birthday party for its employees, fostering a sense of unity and joy within the company. The event, organized by the HR department, featured cheerful decorations, delicious treats, and heartfelt celebrations, highlighting the close-knit bonds among colleagues. Emphasizing teamwork and mutual growth, JINPAT prioritizes a people-first approach, creating a harmonious work environment. Committed to innovation and customer satisfaction, JINPAT delivers high-q

-

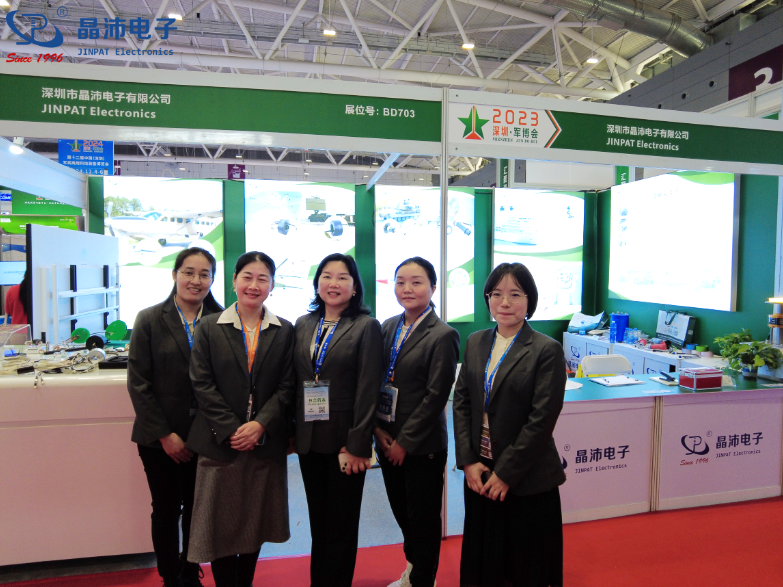

JINPAT has been invited to the 11th Shenzhen Military Expo to explore new opportunities

JINPAT participated in the 11th Shenzhen Military Expo from December 6th to 8th, 2023, showcasing its innovative slip ring solutions and engaging with industry peers to explore collaboration opportunities. With nearly 30 years of experience, JINPAT demonstrated its technical expertise and diverse product portfolio, attracting numerous visitors. The company emphasized its commitment to quality and innovation, aiming to support global industrial development. Through this event, JINPAT highlighted